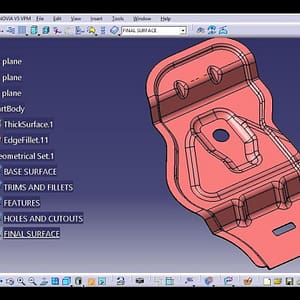

Description

FE-SAFE — The Durability Suite

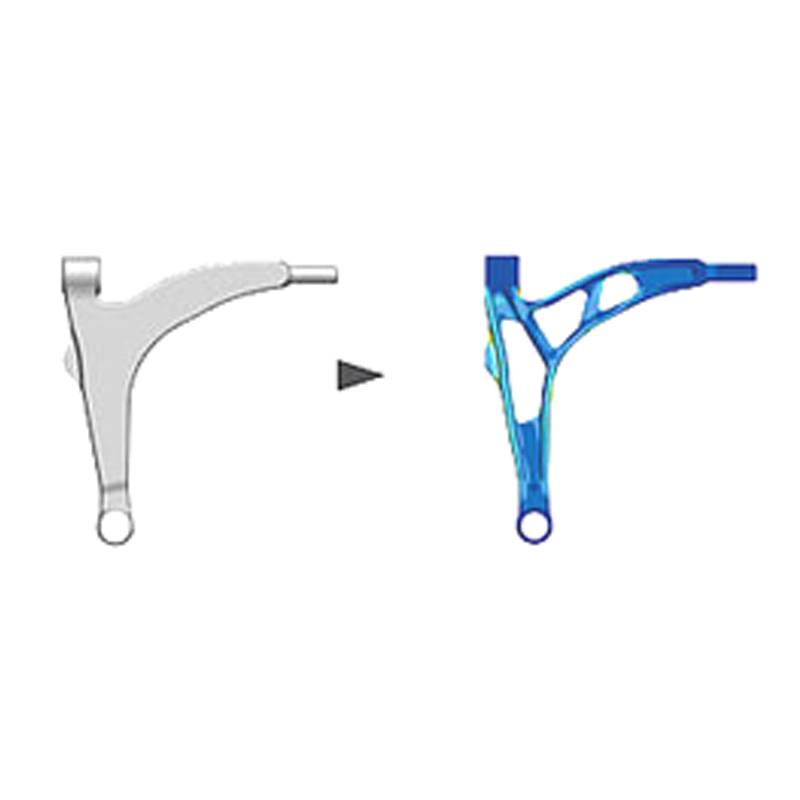

fe-safe, from the SIMULIA brand of Dassault Systèmes, is the world’s leading technology for durability analysis. Its capabilities have been developed to meet the most demanding industry applications. fe-safe is used by leading companies in the automotive, truck, off-highway, marine, military, off-shore, power generation, wind energy, medical engineering and many other industries.

The first commercially available fatigue analysis software to focus on modern multiaxial strain based fatigue methods.